AD138 Application:AduiQ7 4.2L;model year:2002-2016

The core introduction of the product: high adaptability, wear resistance, no abnormal noise, and reduced wear. It can meet the needs of customers for products, enhance the market competitiveness of Schneider products, and help dealers and users more accurately adapt to vehicle models.

Timing belt: 1. Long service life, high reliability, compact structure, quiet sound. 2. Rubber material has -40 ° to -140 °, extremely high tensile strength and length stability. (HNBR) 3. Affordable, long service life, low belt transmission resistance, ensuring normal power output and acceleration performance of the engine. 4. Adopting international unified belt technology, with fine detail processing.

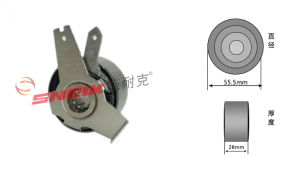

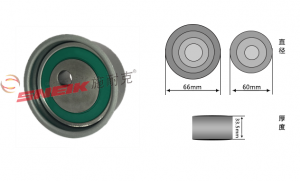

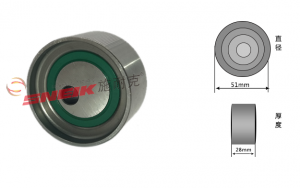

Gear train: Tensioning gear train is a belt tensioning device used in automotive transmission systems, mainly composed of a fixed shell, tensioning arm, wheel body, torsion spring, rolling bearing, and spring sleeve. It can automatically adjust the tension according to different degrees of belt tightness, making the transmission system stable, safe, and reliable. Tensioning wheel is a vulnerable part of automotive and other spare parts. The belt is prone to elongation over time. Some tensioning wheels can automatically adjust the tension of the belt. In addition, with tensioning wheels, the belt runs more smoothly, has less noise, and can prevent slipping. Our gear train quality is stable, with annual after-sales quality issues of less than 1%. We have a large and comprehensive supply chain system, a professional and complete after-sales team, and a factory quality standard system that fully follows international standards.